ANTARES – Crack Detection

Raise the efficiency of your production

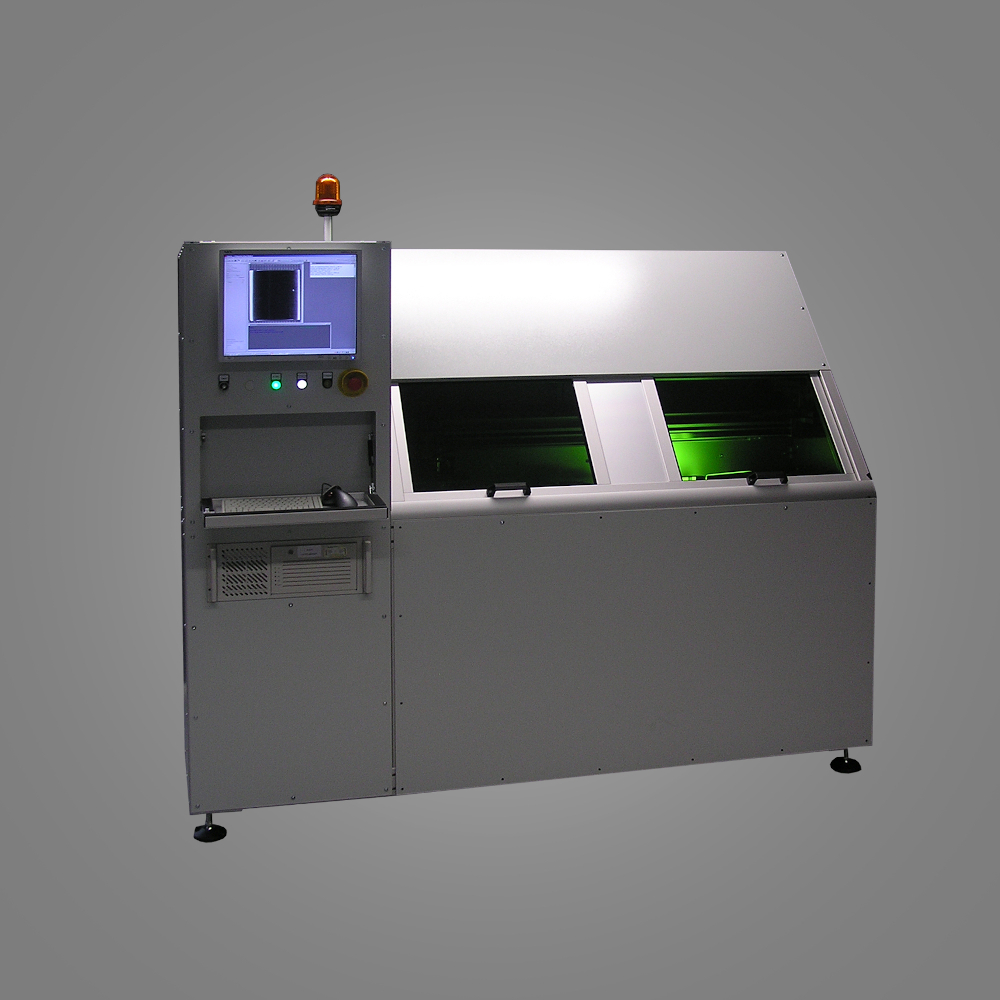

Microcrack detection is an important tool for wafer, cell and module production. With the new ANTARES system, a reliable tool for automatic detection of cracks in individual wafers and cells is available. The quality of the crack images is no longer degraded by grain boundaries or other structures, as it is often seen in electroluminescence (EL) or photoluminescence (PL) images.

Performance data

The ANTARES inspection system can inspect mono- and polycrystalline wafers and cells of 156 × 156 mm² and has a throughput of 4.000 wafers respectively 2.400 cells per hour. These high rates allow the use in up to date production lines.

ANTARES works contact-free by using NIR (1450 nm) lasers and cameras and is not disturbed by metallization and the natural grain structure.

Key facts for ANTARES wafers

- Detection of cracks and inclusions

- No pseudo defects resulting from grain structure

- Cycle time 0.9 s

- Maximum conveyor speed 500 mm/s

- Inspection on-the-fly

- Position accuracy +/- 5 mm

- Contact free alignment

- Generation of density maps for defects

- Maintenance free, high-powered NIR laser

Key facts for ANTARES cells

- Detection of cracks and inclusions

- No pseudo defects resulting from grain structure and metallization

- Cycle time 1.5 s

- Maximum conveyor speed (depending on bow) 250 mm/s

- Inspection on-the-fly

- Position accuracy +/- 5 mm

- Contact free alignment

- Generation of density maps for defects

- Maintenance free, high-powered NIR laser

Further options

The inspection system is available as an inline tool (to be integrated above existing conveyor belts). There are also several other models available, e. g. for integration into stringers, a stand-alone system including sorting out of defect cells and a manual station for single cell inspection.

If you require an individual solution, do not hesitate to contact us directly.

Your contact for the ANTARES system

Andreas Eckl

+49 9131 61082-0

Contact