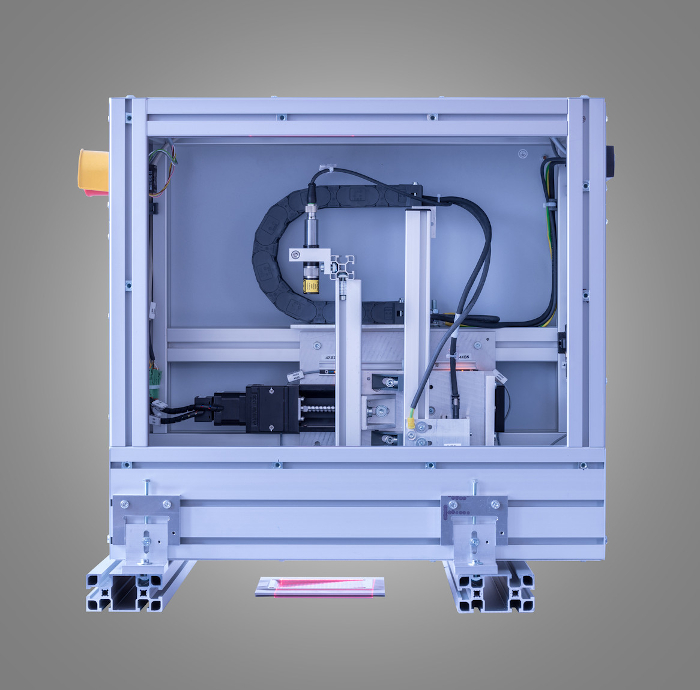

Corus 3D Measurement System

Raise the efficiency of your production

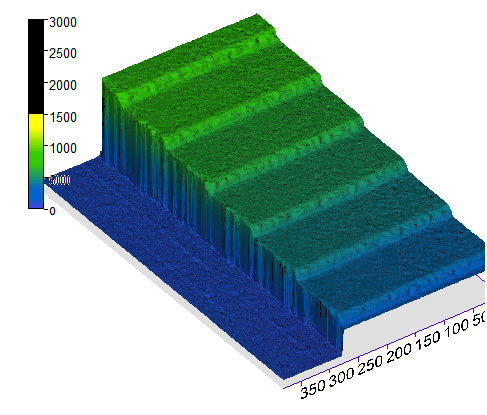

In industry, 3-dimensional measurement of flat components is often required. Our CORUS 3D profile scanner based on the laser triangulation measurement method provides fast and accurate measurement data of components such as metal plates, fuel cells, gaskets or sealants and many more.

Criteria

- Surface and volume defects (protrusion, cracks, particles, inclusions, grooves, bumps, spikes, chippings)

- 2D Measurement integration possible

- Training via CAD-data possible

- Mechanical Interface (Profibus, Ethernet/IP, etc.)

- Complex statistics

- Evaluation of structures

- SQL database for results

Specifications

- Handling: Integration into existing line

- Camera: single or multiple matrix cameras

- Resolution: 1 µm -10 µm

- Lighting: Laser class 1

- Automation: Linear axis for moving the measuring head

- Cycle time: 0.5 s for an area of 150 mm x 150 mm

- Software: Intego Inspector and custom GUI

Performance data

The system can be integrated into existing production lines or equipped with customer-specific automation. In addition, there are many individual adaptation possibilities regarding interfaces, cycle time, resolution and illumination.

If you have an inspection or measurement task that cannot be solved by laser triangulation, we offer additional measurement methods such as confocal chromatic sensor or white light interferometry.

Further options

If you require an individual solution, Intego offers free-of-charge feasibility studies based on sample parts. The prepared study will include a system design with draft specifications and a price estimate. Do not hesitate to contact us directly.

Your contact for the CORUS measurement system

Andreas Eckl

+49 9131 61082-0

Contact