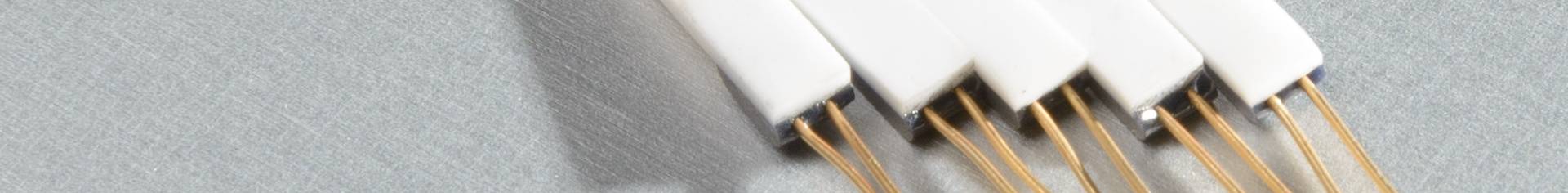

Ceramic Inspection

Raise the efficiency of your production

Ceramics offer ideal properties for many different applications in power electronics, medicine and industry. The mechanical integrity of the finished ceramics is often decisive for the functionality of the later application. With the help of our systems an automated 100% quality control of your ceramic production is possible. The collected defect data provides you with starting points for optimizing your manufacturing process in the form of statistics.

Criteria

Special attention should be paid to mechanical defects:

- Cracks and micro cracks, flaking and chipping

- Scratches, particles and sinter residues

- Inclusions, bubbles and discoloration

- Geometry measurement (flatness, apertures, dimensions, completeness)

- Defects within multilayer ceramics using thermography

Performance data

Such defects can lead to breakage and thus to failure of entire components. Identification of adhering particles is also crucial. Our inspection systems are able to inspect raw ceramics, partially processed ceramics as well as printed circuits with different geometries, PCB layouts and different assembly levels, and also finished modules. The chemical composition of the ceramic as well as color and surface treatment have only little influence on the test methods we use. Especially no dye is needed in order to find defects.

The possible inspection objectives of circuit carriers may include:

- Print layout (structure, width, short circuits)

- Bonded electronic components (arrangement, completeness)

- Functional test of components using thermography

Further options

If you require an individual solution, Intego offers free-of-charge feasibility studies based on sample parts. The prepared study will include a system design with draft specifications and a price estimate. Do not hesitate to contact us directly.

Your contact for ceramic inspection

Dr. Simone Gaffling

+49 9131 61082-240

simone.gaffling@intego.de