Transmission Measurement for Laser Welding Processes

Raise the efficiency of your production

Due to the manufacturing process and material properties, transmission variations along the welding path appear in the transparent joining partner which can decisively influence the welding process. Thus, there can be an increased reflection and therefore reduced transmission of the laser radiation in regions of e.g. accumulated glass fiber content. As a result, this area will be affected by an increased energy loss, so that only a reduced amount of laser energy will be available for the actual welding process. By using the appropriate Intego system, the transmission profiles are determined. Accordingly, with knowing these profiles the welding technology of Evosys Laser GmbH enables the customer to adjust the process to the locally varying transmission characteristics of the plastic component. This leads to a constant energy input of the joining process and a consistent high quality of the weld seam. With our EvoInspect systems we offer you solutions for the:

- Radial transmission measurement

- Planar transmission measurement

- Customer specific transmission measurement

Performance data

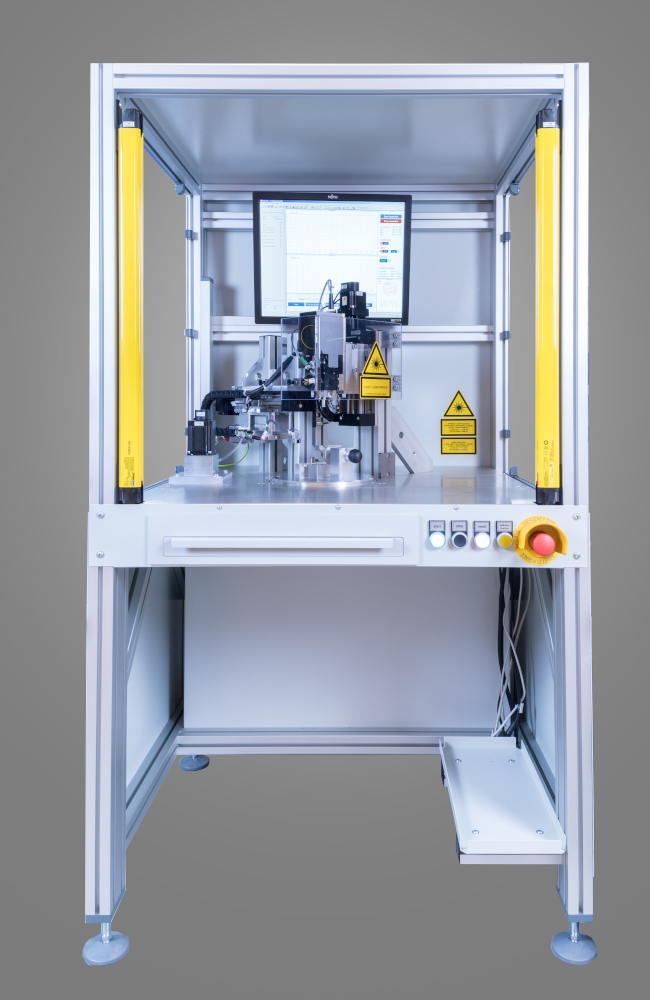

To get a reliable forecast of the transmission behaviour of an assembly, it is useful to create a transmission profile along the intended weld seam. Intego's transmission measurement systems, which comply the DVS guideline 2243, are equipped with a laser/sensor unit, allowing a simple and reliable determination of the transmission values of common plastic parts. It is possible to trace either preselected contours, or individual positions within the plastic parts with the help of the integrated motorized xy stage. With corresponding adjustments of the part fixture, welding contours of new components can easily be trained by means of common CAD file types like dxf. The determined transmission values and profiles can be either passed to a MES or be used for a customized power control of the laser beam for the welding process.

In the right figure, exemplary transmission profiles of four equal automotive components are shown. The variations of the transmission along the planned laser welding contour are clearly visible. The recorded transmission profiles can be submitted to the laser welding to ensure a constant energy input while the entire process.

Intego offers reliable and applied custom solutions to obtain precise transmission profiles in plastic components. The transmission measurement systems will be calibrated before and during every measurement. Together with the ambient light independent electronics and the constant calibration procedure a high resolution and reproducibility will be achieved.

Important system specifications

- Transmission measurement at e.g. 980 nm (laser class 1)

- Customized beam diameter (e.g. 1 mm)

- Large sensor aperture (up to 10 x 10 mm2)

- Resolution ≤ 0.1 % transmission

- Space for large component size

- Height adjustable sensor position (lab tool)

- Pilot laser or camera based measurement point visualization

- Transmission measurement is independent of any ambient light

- Transmission profiles in a few seconds

- Measuring points and contours can be defined manually or by CAD-data

- Interface to MES or following welding process

- Tool calibration (using normals which were measured acc. DIN EN ISO/IEC 17025), separate calibration is available

- Component-specific system adjustments possible

- System design either standalone or line

Further options

The transmission measurement systems are suitable for highly automated manufacturing lines, e.g. in the automotive industry, for special environmental conditions. Intego additionally provides weld seam inspection systems and automation solutions for part handling, assembly or sorting.

If you require an individual solution, Intego offers free-of-charge feasibility studies based on sample parts. The prepared study will include a system design with draft specifications and a price estimate. Do not hesitate to contact us directly.

Your contact for transmission measurement

Dr. Steffen Oppel

+49 9131 61082-0

Contact