01 Solar Ingots

Ingot Inspection

Raise the efficiency of your production

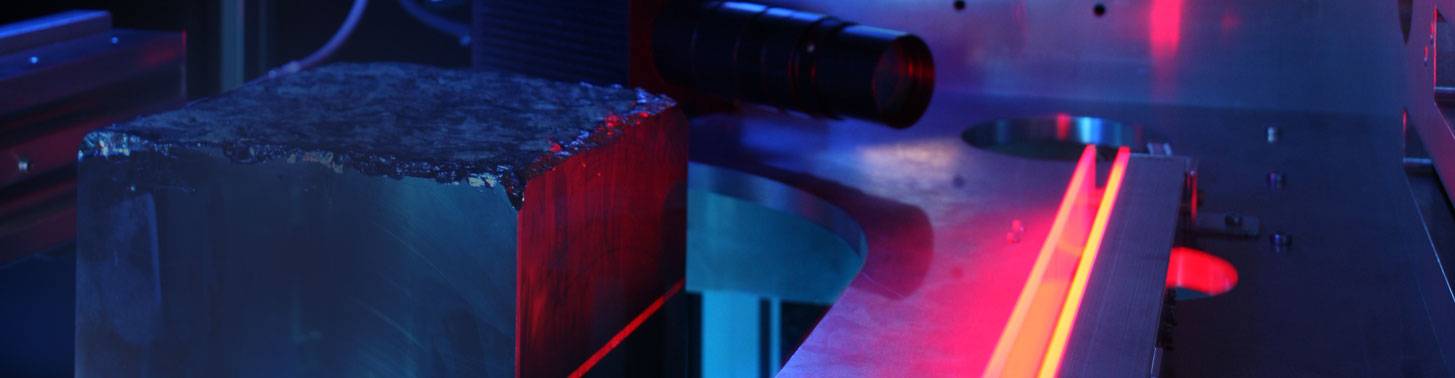

From the silicon raw material, crystal ingots are grown, which are sawn into the silicon blocks. It is reasonable to sort out faulty parts as soon as possible or, even better, to avoid processing them. Our ORION silicon block inspection systems offer a fully automated solution for inspection prior to the two process steps of polishing and wafer sawing:

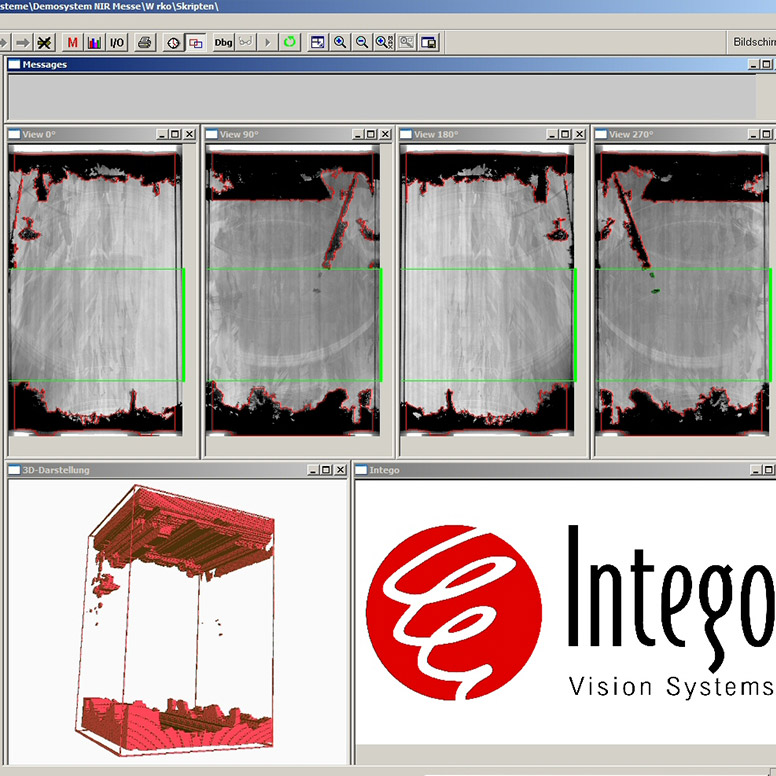

- The ORION NIR inspection generates cutting recommendations for the wafer sawing process. With knowledge of the inclusions in the material, a suitable process solution can be found.

- The ORION 3D geometry measurement system generates recommendations for the polishing system to reduce the polishing effort.

The automatic inspection of silicon blocks is suitable for continuous automated production and for manual operation as a stand-alone system, e.g. for the laboratory. It is possible to combine the two systems into one machine.

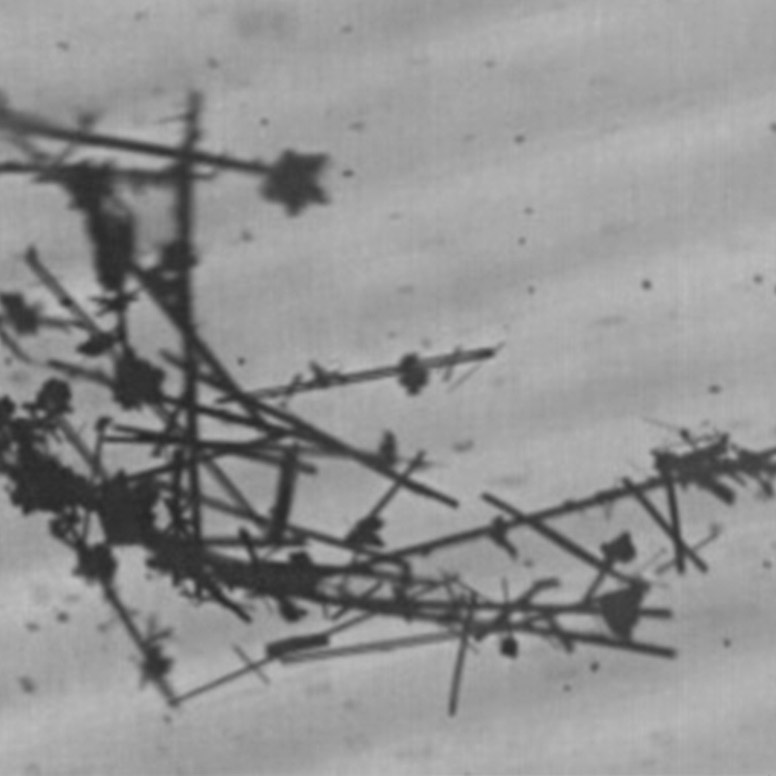

ORION NIR inspection

- Detection of smallest structures of SiN/SiC inclusions

- Resolution down to 18 µm

- Generation of cutting recommendations

- 3D reconstruction of the inclusions in individual blocks and in whole ingots

- Maintenance free NIR lighting

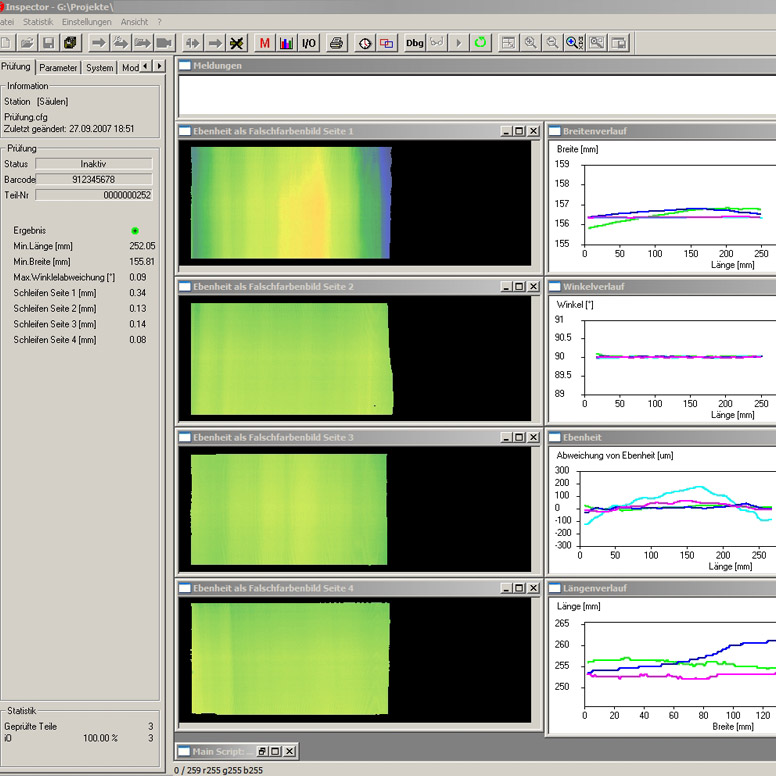

ORION 3D geometry measurement

- Measurement of length, width and height

- Ascertainment of angularity, squareness, flatness and tilt angle

- Exact measurement of the chamfers

- Detection of chippings, grooves and other defects

- Generation of grinding recommendations

Your contact for ingot inspection

Andreas Eckl

+49 9131 61082-0

Contact