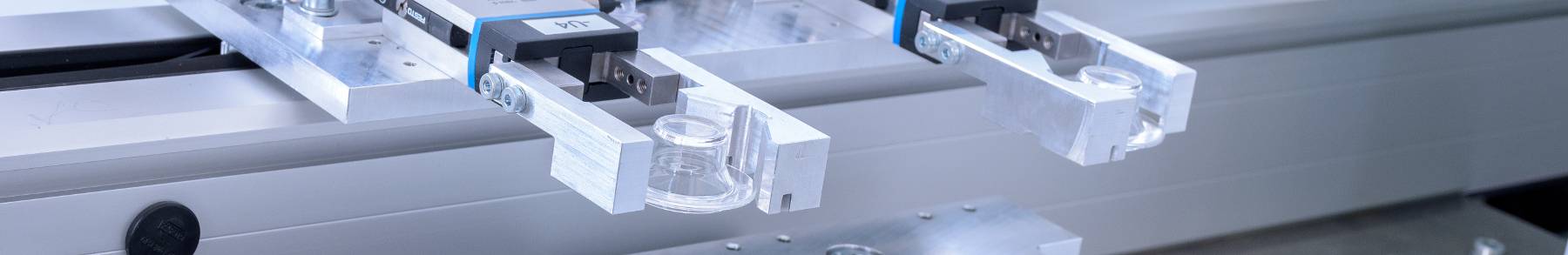

Lens inspection

100% inspection of optical cleanliness and function

Lenses made of glass, plastic or silicone are used as beam-shaping elements in numerous industries such as medical and telecommunications technology, in the automotive sector, as laser optics or in optical sensors. In order to fulfill their intended purpose, the surfaces and volumes of the lenses must be free of defects and foreign bodies. In addition, compliance with shape tolerances is an essential prerequisite for correct optical function and mechanical integration into assemblies.

Coverage of many inspection tasks

To ensure quality in the production of lenses, various potential defect types must be detected:

- Surface imperfections (e.g. scratches, holes, chipping, soiling)

- Material imperfections (e.g. bubbles, inclusions, inhomogeneities, streaks)

- Coating defects, discoloration, clouding

- Surface shape deviations

- Centering error

- Dimensional deviations (e.g. center thickness, sprue separation)

- Functional tests:

- Measurement of focal length and/or magnification

- Measurement of imaging quality (modulation transfer function MTF)

- Assembly testing (tilting, position error)

Intego's inspection systems are able to carry out all these tests fully automatically - if desired, also combined in a single machine.

Customized use of various measurement techniques

Different technologies are integrated in Intego's systems to fulfill the testing tasks, including

- High-resolution matrix and line scan cameras

- Optimized light sources

- Confocal, triangulative, interferometric or deflectometric sensors

- High-precision actuators

The optimum measurement technology and components are selected on a customer-specific basis according to the parts to be tested and the test requirements.

Customized software

Data acquisition and part handling are controlled by the in-house software and the measurement data is evaluated in parallel. The parts under test are classified according to standards (e.g. DIN ISO 10110 or scratch/dig according to MIL/ANSI) or adapted to the customers' specific requirements. In addition to classic image processing, deep learning

methods are also used.

The systems' graphical user interface displays live machine status and test results to the operator. All relevant information, including defect maps, quantities, dimensions, etc., is visible at a glance. The storage of the results data ensures complete traceability of all parts and also allows subsequent analysis of the recorded data.

Automation and interfaces

Intego offers its inspection systems as stand-alone systems with manual loading, e.g. for laboratory use, or as inline systems for integration into automated production lines.

Almost any interface can be implemented for communication with external handling systems or

sensors as well as connection to customer databases.

Contact us

Feel free to contact us if you are interested or have any questions. You will find contact details

at the top right of this page and under Contacts. Intego also offers free preliminary studies

based on sample parts. With the study you will receive a system concept with a price estimate