Fuel Cell Inspection

Raise the efficiency of your production

Clean independent power generation where it is needed has long been possible with fuel cells. Currently there is a growing demand for solutions to implement the energy turnaround and as part of the electromobility offensive. The quality of the fuel cells determines their efficiency, service life, safety and function. Intego offers optical solutions from substrate inspection to the finished fuel cell stack. The collected error data allows an early intervention in production to prevent faulty parts and cells. In addition, the data in the form of statistics provides you with starting points for optimizing your manufacturing process.

Criteria

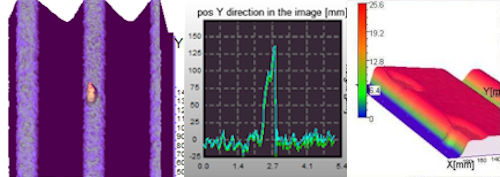

- Substrate testing of various materials (e. g. ceramics, sintered metal plates with and without ribs, silicon) for defects such as cracks, pinholes, particles, chippings, etc.

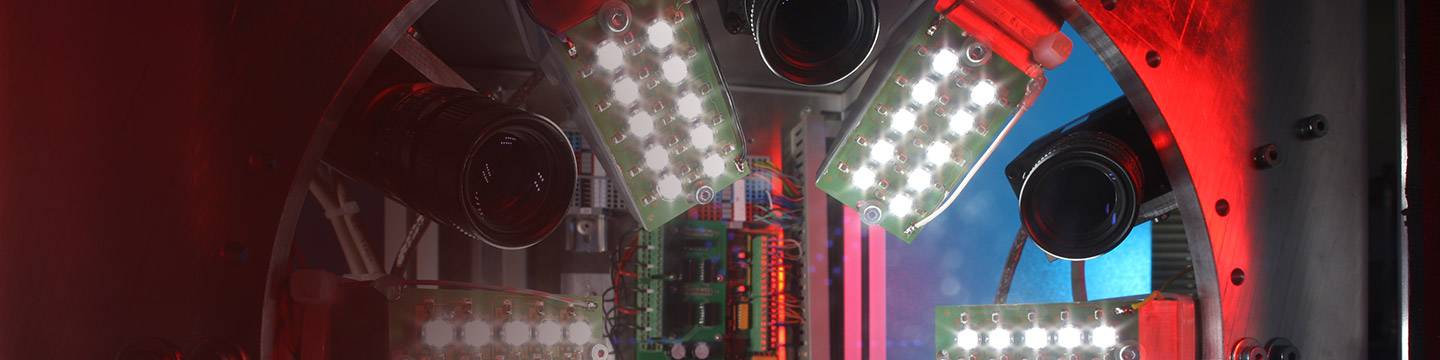

- Print and coating quality

- Transmission or thermographic measurements to determine the layer thickness

- CORUS 3D topography inspection to determine the mass flow (can also be combined with other inspections)

- Inspection of finished stacks

Performance data

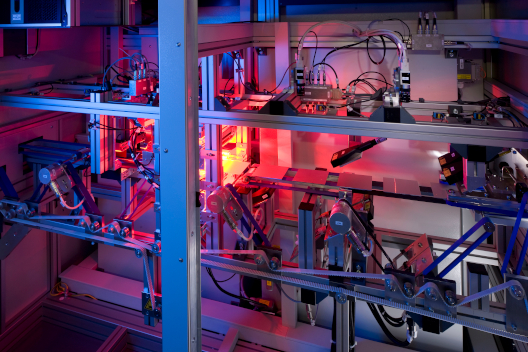

We offer both standard solutions and customer-specific solutions for the various testing and measuring tasks in fuel cell production. In most cases, our systems are integrated directly into the production line, but can also be laid out for use in research and development.

Further options

If you require an individual solution, Intego offers free-of-charge feasibility studies based on sample parts. The prepared study will include a system design with draft specifications and a price estimate. Do not hesitate to contact us directly.

Your contact for fuel cell inspection

Dr. Alexander Kessel

+49 9131 61082-290

alexander.kessel@intego.de