K&G - Sapphire Boules

Boule Inspection

Raise the efficiency of your production

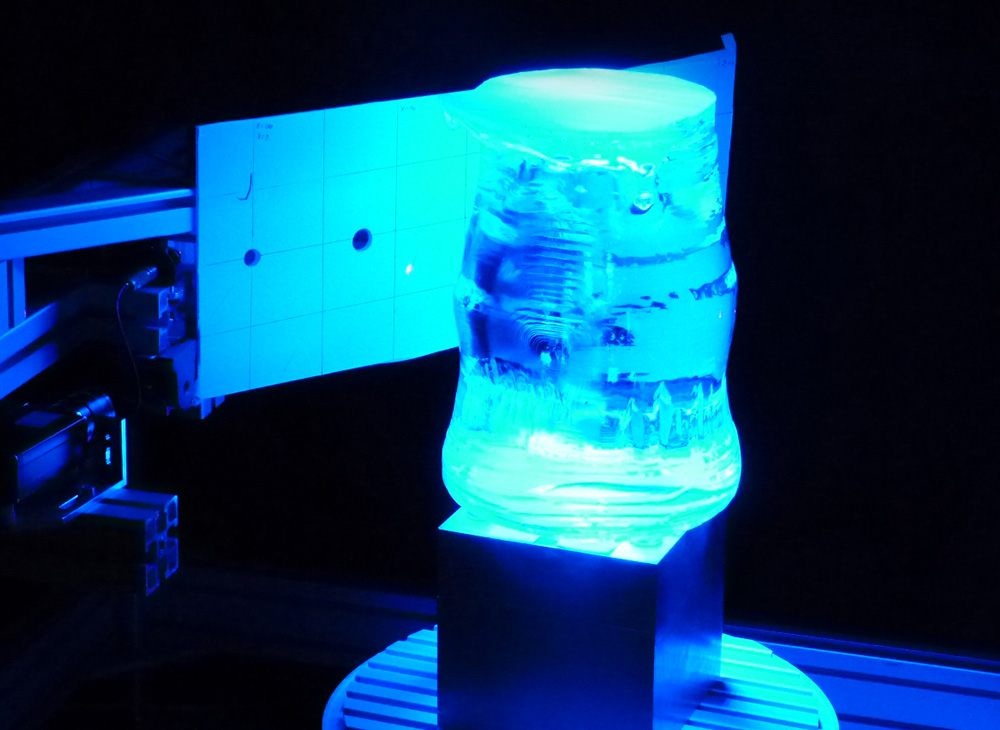

Sapphire boules created by the Kyropoulos method have a clear but uneven surface, making optical inspection rather difficult. With advanced image processing techniques, Intego has achieved the ability to look inside the unrefined boule.

Performance data

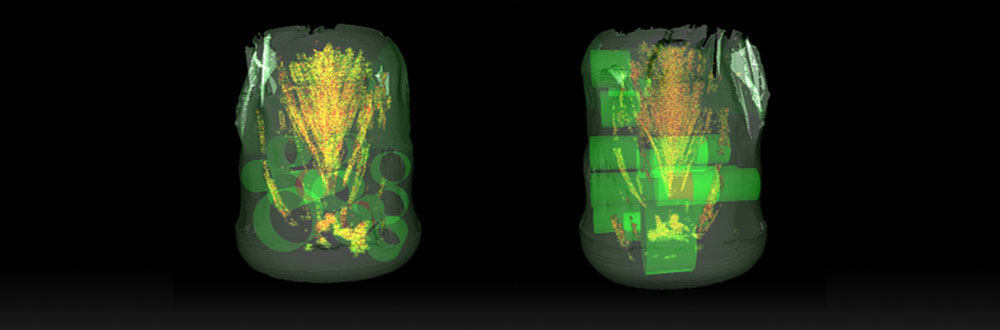

- Inclusions and smoke detection: Find small inclusions within the boule and visualize the defect concentration in the 3D model.

- 3D geometry measurement: Create a 3D model of the boule's outer shape.

- Yieldmax: This feature provides optimized coring suggestions based on the 3D defect model. The software package finds the ideal coring points with various drilling diameters, ranging from 1" to 8".

- Machine connectivity: The optional datalink enables you to exactly position and turn the boule for milling within a CNC-mill for highest yield.

- Various options: Weighing, barcode scanning, roughness measurement.

Technical option

For boules created by other methods, please refer to our slab inspection tools.

Further options

If you require an individual solution, Intego offers free-of-charge feasibility studies based on sample parts. The prepared study will include a system design with draft specifications and a price estimate. Do not hesitate to contact us directly.

Your contact for boule inspection

Andreas Eckl

+49 9131 61082-220

andreas.eckl@intego.de