MODULUM – Luminescence Measurement

Raise the efficiency of your production

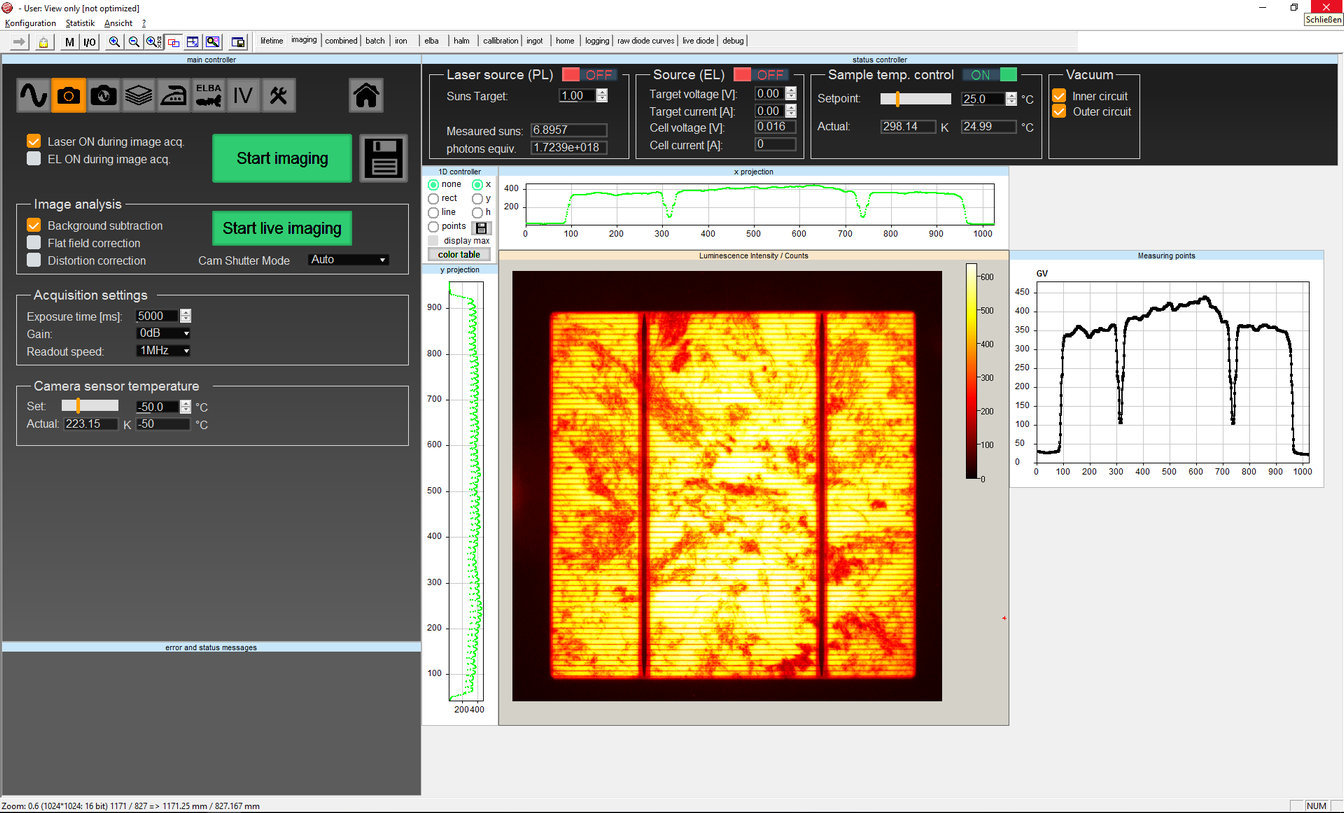

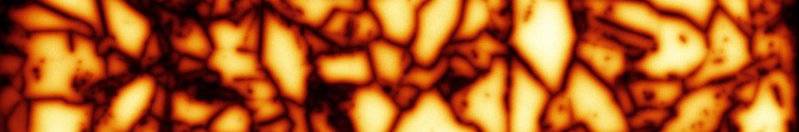

This system for luminescence measurements was developed with the Fraunhofer Institute for Solar Energy Systems (ISE) especially for the solar sector. It enables consistent material analysis across the entire product range from ingots, through wafers, to finished cells and modules. In addition, the system is ideally suited for the in the semiconductor industry for testing and characterizing e.g. silicon, SiC, Ge, GaN, GaAs, LEDs/µLEDs and OLEDs. Electroluminescence and photoluminescence as well as combinations of these methods are used for image acquisition. The system can be used for various applications such as spatially resolved charge carrier lifetime measurements, determination of iron concentration and measurements for efficiency estimation of wafers (ELBA). In addition, further user-defined measuring sequences and evaluations can be integrated.

Specifications

- System dimensions: 2 m x 2.1 m x 1.1 m

- Large volume for the measurement of ingots, wafers, cells and mini modules:

0.17 m x 1.1 m x 0.9 m - Large field of view: 170 x 170 mm² (larger on request)

- Manual height adjustment of the measurement table

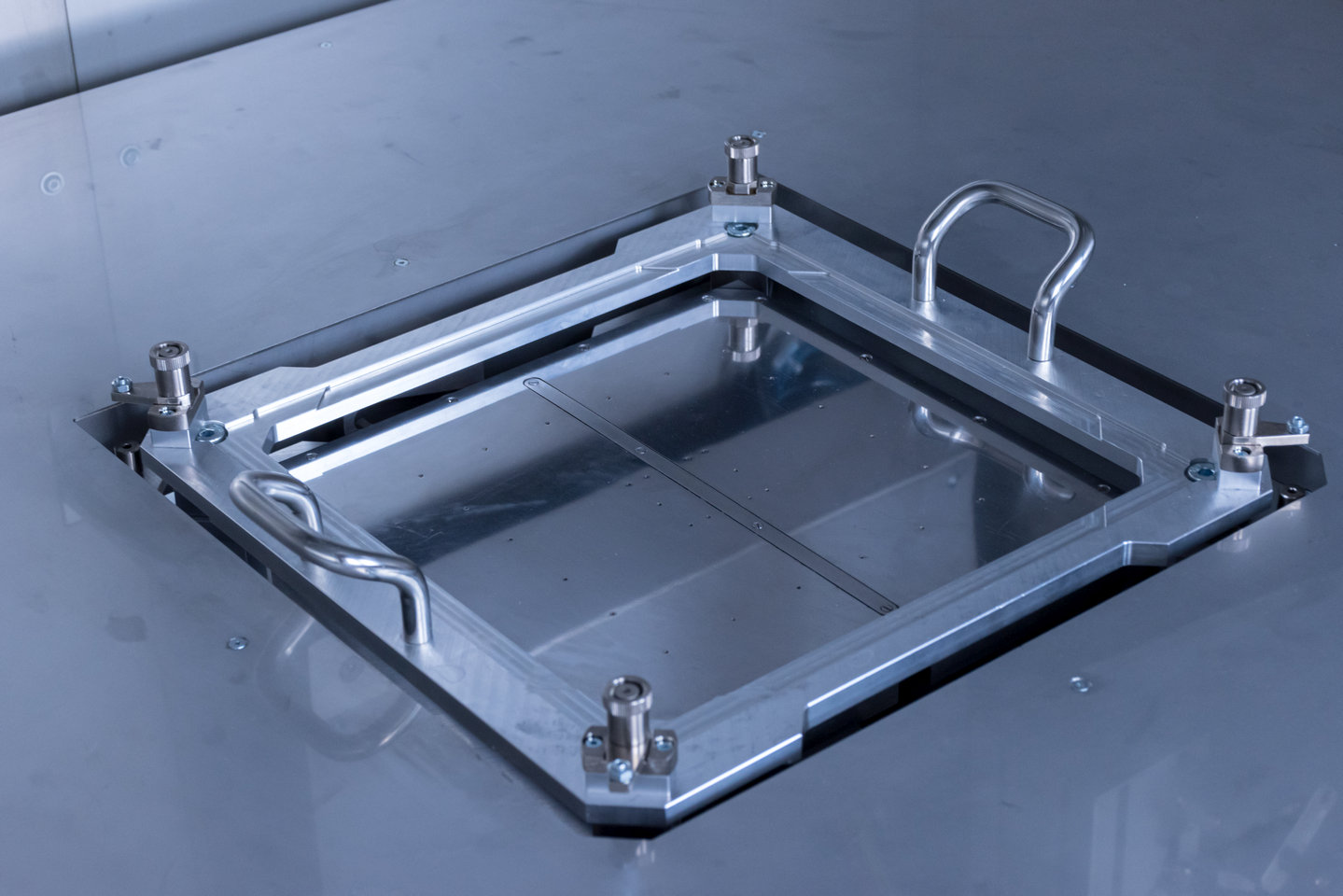

- Vacuum chuck for fixation and temperature control (25-80°C) of test specimens

- Laser illumination:

- wavelength: 808 nm

- intensity: 0.1 - 2 suns

- spatial homogeneity deviations: < 10 %

- temporal modulation of the output power

- adaptations such as a second laser source are possible on request

- Electrical contacting:

- back-side contacting via chuck

- front-side contacting via adaptable frame with contact bars

- Si-based camera with deep-depletion for minimal dark current

- cooled to -70°C

- standard resolution: 180 µm

- spectral limitation: 950 nm - 1000 nm

- adaptable on request

- Photodetector:

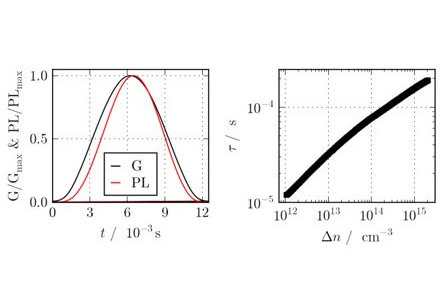

- time-resolved measurement of injection and luminescence response of the sample

- high sensitivity due to optimized photo diode setup with low-noise current amplifier

- Typical measuring time of 1-10 seconds, for complex measuring procedures also hours to days

Performance Data

The system is especially designed for use in research and development and can be flexibly adapted to different measurement tasks. Customer specific hard- and software solutions can be integrated on request. Of course, the measuring principle can also be transferred to an inline application.

Further options

If you require an individual solution, Intego offers free-of-charge feasibility studies based on sample parts. The prepared study will include a system design with draft specifications and a price estimate. Do not hesitate to contact us directly.

Your contact for the MODULUM system

Dr. Alexander Kessel

+49 9131 61082-290

alexander.kessel@intego.de