ORION – NIR Inspektion

Raise the efficiency of your production

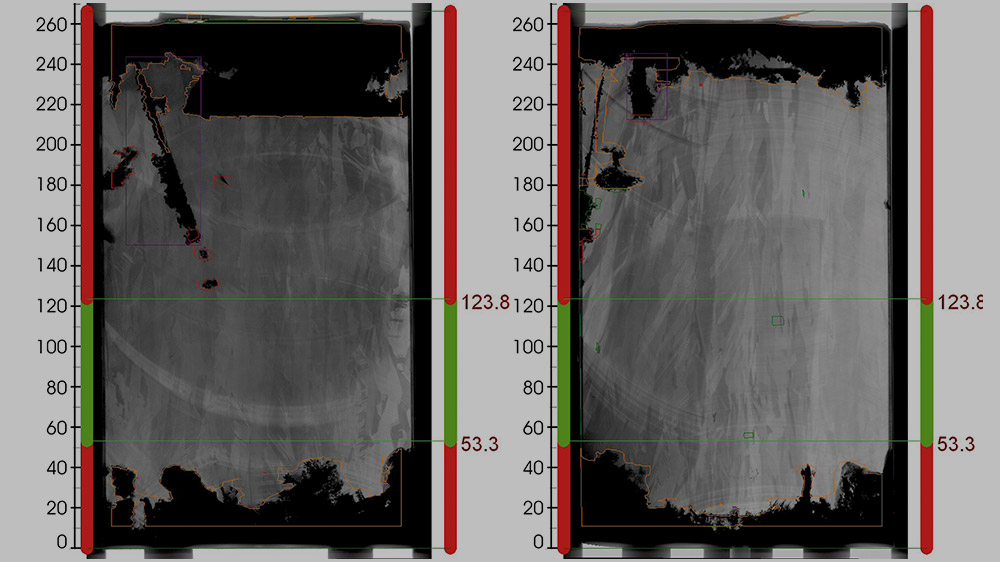

Detection of hard inclusions, e.g. SiC, in multicrystalline silicon bricks is vital for ensuring the stability of the subsequent wafering process. Other inclusions, e.g. Si3N4, may reduce the efficiency and mechanical stability of the wafers and cells. In particular, wafering with diamond wires is very sensitive to the smallest (< 0.1 mm) hard particle inclusions and introduces a requirement for high resolution NIR inspection to detect such particles prior to the wire sawing process. Furthermore, impressively detailed images and 3D maps of inclusions will enable you to optimize your crystallization processes.

Performance data

The ORION NIR inspection system can handle brick sizes up to 210 × 210 × 1000 mm³ and has cycle times from 1 to 5 min per brick depending on the system configuration, the brick length and on the required accuracy.

Key facts

- Detection of the smallest Si3N4/SiC inclusion structures

- Generation of cutting recommendations

- Generation of density maps for defects

- Maintenance free, high-powered NIR Laser

Technical options

- Combination with Intego’s ORION 3D geometry measurement

- Roughness measurement

- Marking station for cutting recommendations

- Weighing

- MDP lifetime measurement

- Barcode scanner

The standard image resolution for inline use is 100 μm. In addition, we can offer the ORION SHR (Super High Resolution) system with an unsurpassed resolution of 18 μm, making it the ultimate tool for ensuring the quality, stability and efficiency of your further processing steps and your final product.

Best image quality

The pixel resolution of 18 µm, the brilliant focus throughout the entire brick and rich contrast enable detection of the smallest needle-like defects and SiC particles – prerequisites for establishing a stable diamond wire cutting process. Optimize crystallization by seeing exactly what kinds of inclusions are present and where they are located within the whole ingot. Last but not least: Increase yield by reducing false rejections.

Lab or production environment

The automatic inspection of silicon blocks is suitable for continuous automated production as well as for manual operation as a stand-alone system, e.g. for the laboratory.

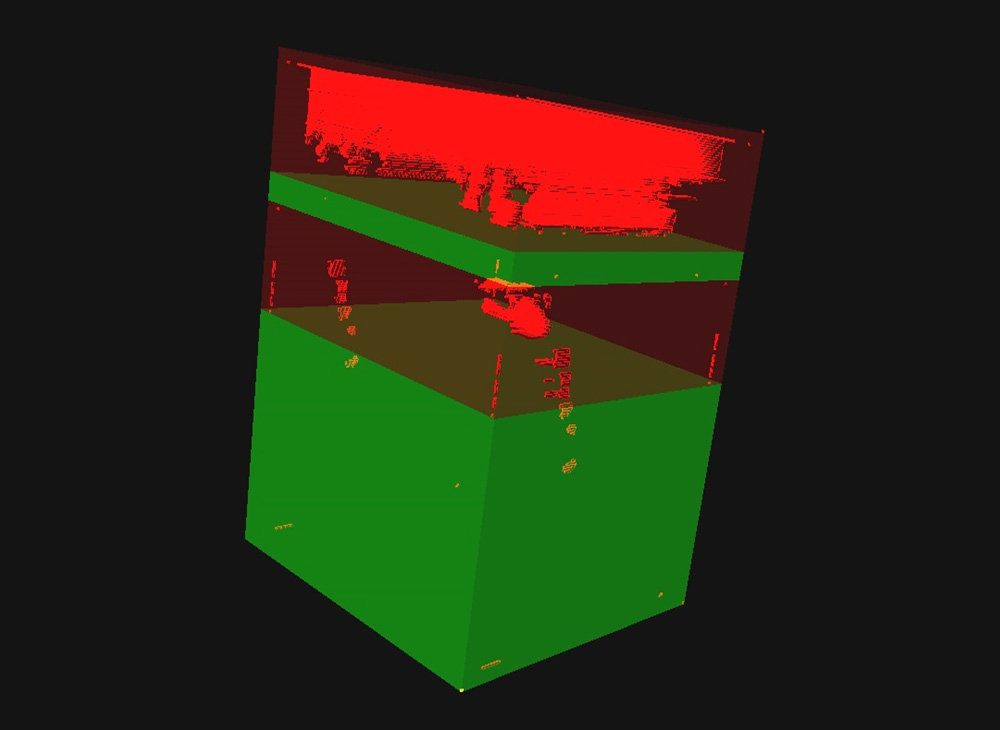

Intego ORION systems feature an easy to use, state of the art graphical user interface. Diverse options for the 3D representation of results, the defect density plots, the export of user configurable PDF reports and even the generation of movies of a virtual flight through the brick only take a few mouse clicks.

Results are shown on a user monitor, where system parameters can be changed, inspection results can be supervised and external operating signals can be tapped. The results can also be communicated to an existing automation and/or MES (e. g. by Profibus, ethernet). GEM/SECS, Semi E10, XML are supported and customer specific protocols can be integrated on request.

Further options

If you require an individual solution, Intego offers free-of-charge feasibility studies based on sample parts. The prepared study will include a system design with draft specifications and a price estimate. Do not hesitate to contact us directly.

Your contact for the ORION NIR system

Andreas Eckl

+49 9131 61082-0

Contact