Inspection of Display Covers and Transparent Parts

Raise the efficiency of your production

Transparent parts such as covers, displays or lenses can easily be inspected with automated means. In the plastic processing sector they are normally produced by injection moulding. By using the same methods, displays or lenses of other transparent materials such as glass or sapphire can also be inspected.

Performance data

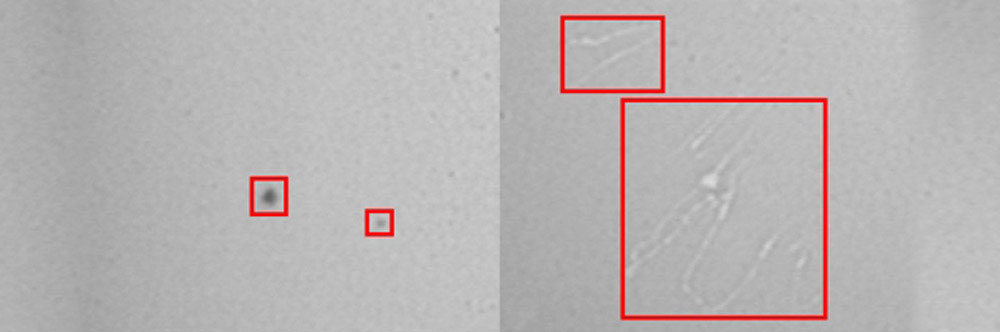

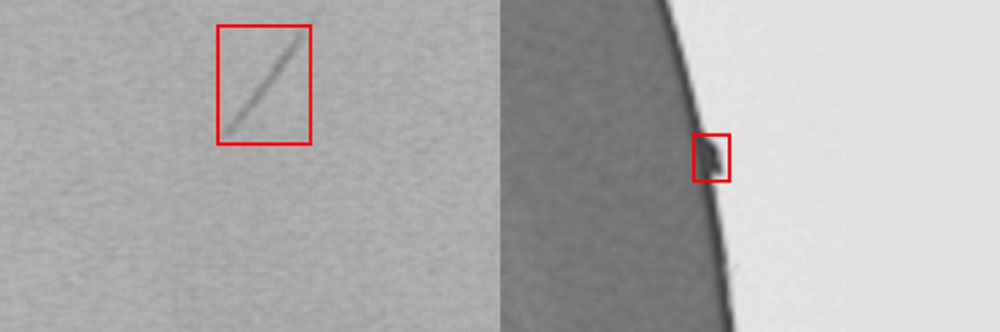

The following defects in parts can be detected automatically and reliably:

- Dark and bright inclusions

- Marks and streaks

- Boundary layers in the material (differences in the refraction index)

- Scratches and seams

- Dimension faults

- Faults in the imaging characteristics of lenses

- Coating defects

Printed or foil decorated areas can be automatically inspected during or after production:

- Print or foil defects (pad printing, IMD)

- Cleaning defects, flakes

- Mounting defects

A statistical record of the defects, e.g. cavities, loads, error locations and types, provides helpful notes for optimizing your production.

Further options

If you require an individual solution, Intego offers free-of-charge feasibility studies based on sample parts. The prepared study will include a system design with draft specifications and a price estimate. Do not hesitate to contact us directly.

Your contact for display cover and transparent part inspection

Dr. Simone Gaffling

+49 9131 61082-240

simone.gaffling@intego.de