Metall - EN

Metal Inspection

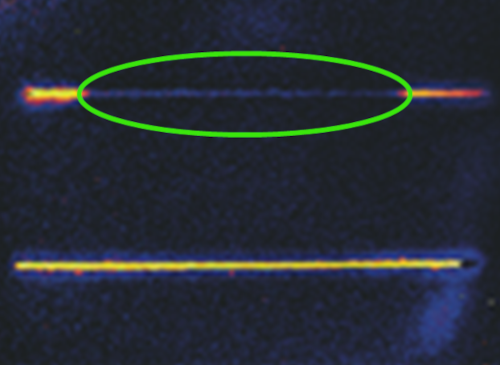

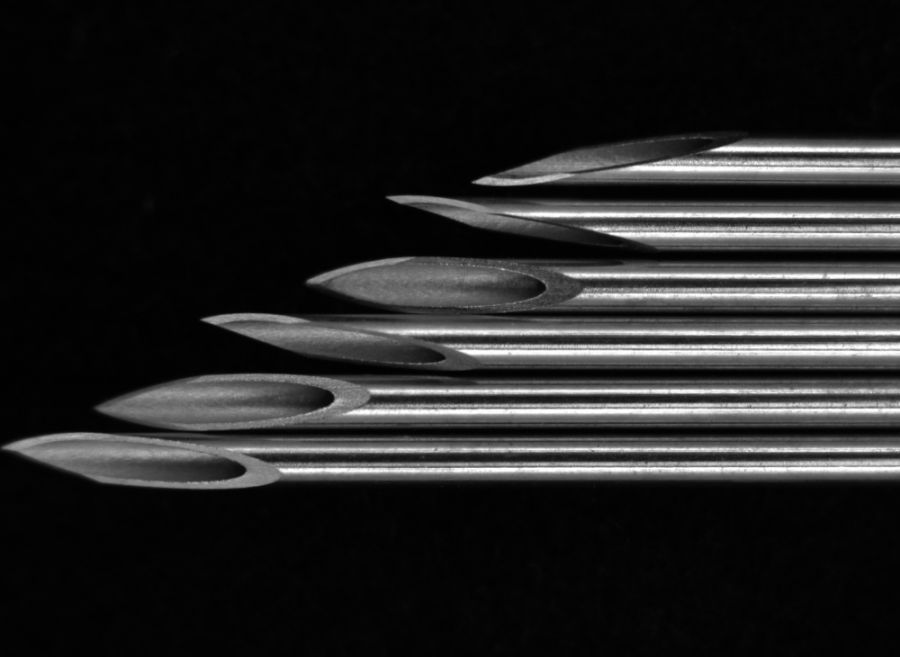

Metallic components and surfaces require reliable inspection solutions. Metals and precious metals as well as various alloys are used in many products and shapes. Intego offers inspection systems for metal pipes, needles and cannulas, as well as fuel cell components and laser welding seams to ensure high quality and functionality. Due to the usually strong structure of the surfaces, specially designed robust methods e. g. measuring procedures are necessary. Our test systems are designed for fully automatic 100% control in industrial environments.