ORION – 3D Geometry Measurement

Technical options

- Combination with Intego’s ORION NIR Inspection

- Weighing

- Barcode scanner

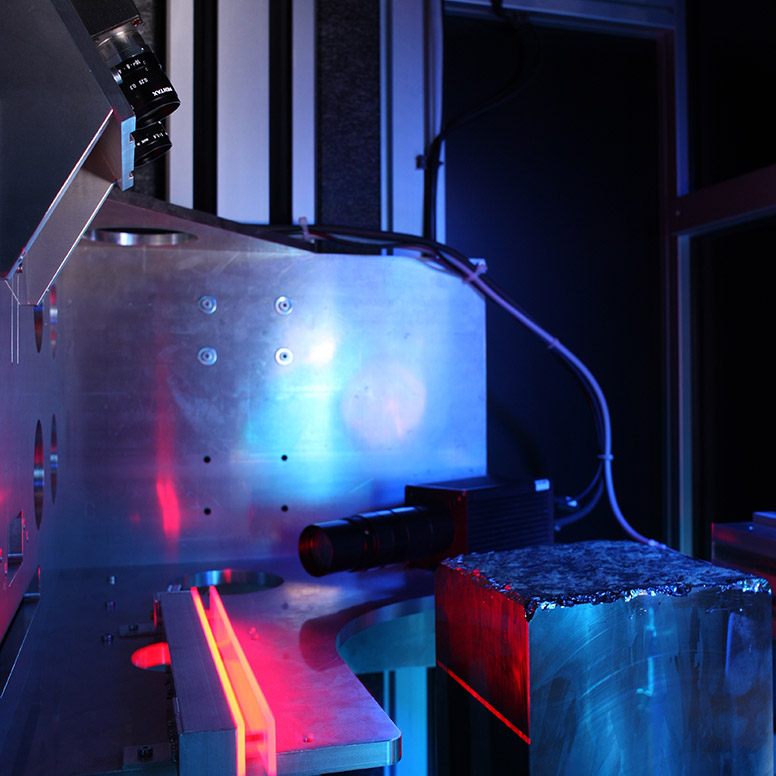

Lab or production environment

The automatic inspection of silicon blocks is suitable for continuous automated production as well as for manual operation as a stand-alone system, e.g. for the laboratory.

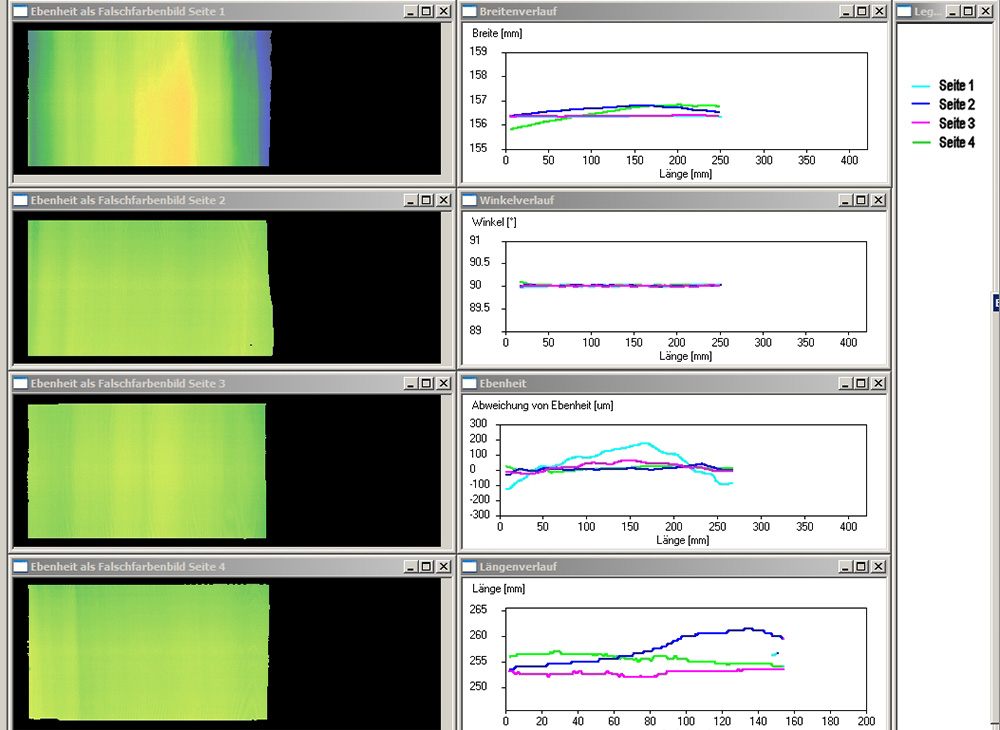

Intego ORION systems feature an easy to use, state of the art graphical user interface. Diverse options for 3D representation of results or export of user configurable PDF reports only take a few mouse clicks.

Results are shown on a user monitor, where system parameters can be changed, inspection results can be supervised and external operating signals can be tapped. The results can also be communicated to an existing automation and/or MES (e. g. by Profibus, ethernet). GEM/SECS, Semi E10, XML are supported and customer specific protocols can be integrated on request.

Further options

If you require an individual solution, Intego offers free-of-charge feasibility studies based on sample parts. The prepared study will include a system design with draft specifications and a price estimate. Do not hesitate to contact us directly.

Your contact for the ORION 3D measurement

Andreas Eckl

+49 9131 61082-0

Contact