APUS – Print and Final Cell Inspection

Raise the efficiency of your production

In manufacturing solar cells, a number of production steps are crucial to cell efficiency. It is therefore important to get immediate feedback on the process quality of each of those steps to enable quick reactions to errors.

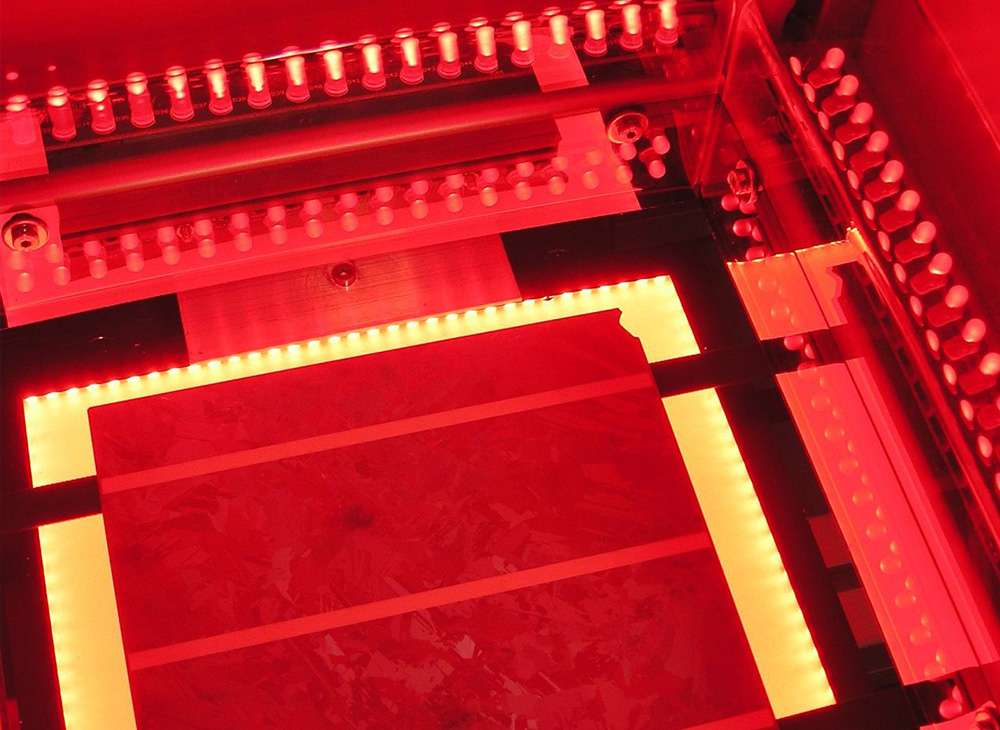

APUS is an image processing system that tests the quality of the screen printing (e.g. the front side, the back field metallization and the back busbar) of the cells. It can be combined with an ARC inspection.

In finding the defects, the APUS print and final cell inspection system helps you to locate and remove sources of errors immediately and, in turn, to increase your production yield. Only tested cells that meet the specifications are allowed to proceed to the next manufacturing steps.

Performance data

The APUS print inspection system has a cycle time of 1 second per cell and is therefore suitable for use with typical automated production lines. APUS works with a high resolution of 20 μm to measure even up-to-date cells with a very thin finger grid.

The inspection system is designed to be integrated directly above the usual transfer systems in production, e.g. conveyor belt systems. The integration into an existing automation can be arranged easily.

Key facts

- Suitable for mono- and multicrystalline cells

- Inspection of back field, back busbar and front print

- Throughput up to 3.600 cells per hour

- High resolution of 20 μm for thin finger printing

- Detection of print misalignment (position and rotation)

- Detection of cell breakage (chippings, edge defects,…)

- Detection of finger and busbar interrupts

- Detection of broad fingers and broad busbars

- Detection of missing paste and paste stains

- Generation of finger width statistics

Further options

For the APUS final cell inspection system an additional color camera is integrated. It is used to measure the ARC layer thickness and detect variations in the coating.

A barcode scanner or similar device can also be integrated into the inspection system. Such a reader allows a comfortable input of screen and paste bar codes. The results can be integrated into the statistical function of the inspection system. The system can be trained to read new print layouts using CAD data or master samples.

Results are shown on a user monitor, where system parameters can be changed, inspection results can be supervised and external operating signals can be tapped. The results can also be communicated to an existing automation and/or MES (e. g. by Profibus, ethernet). GEM/SECS, Semi E10, XML are supported and customer specific protocols can be integrated on request.

If you require an individual solution, do not hesitate to contact us directly.

Your contact for the APUS print inspection

Andreas Eckl

+49 9131 61082-0

Contact