VELA – String Inspection

Raise the efficiency of your production

Manufacturing solar strings for solar modules is a crucial production step, because it is one of the last steps before final lamination. It is important to get immediate feedback about the soldering process to be able to detect the drift of process parameters quickly. With the data from this tool, the production can be optimized to avoid defective parts, thus increasing the overall yield. The VELA string inspection systems can be directly integrated into the stringer machines of known suppliers with little effort.

Performance data

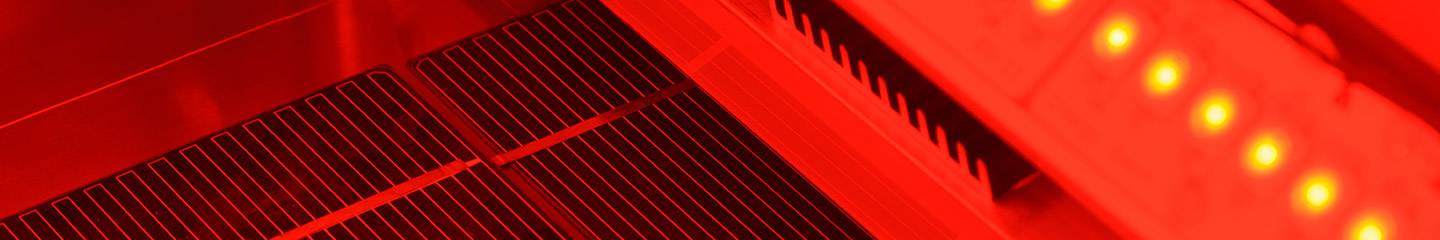

Our vision system is located directly after soldering in the stringer tool. A matrix camera and multiple fast switching maintenance free LED illuminations are used to qualify and measure each individual soldered connection. The tool is capable of inspecting 3 to 6 busbar cells made of mono- or multicrystalline silicon material. The tool can test full and half cut cells.

Key facts

The VELA string inspection system is designed to measure the following defects:

- Incorrect distances between cells

- Incorrect position of the ribbon on the busbar

- Twisted or folded ribbons

- Detection of flux contamination and breakage

Further options

The VELA string inspection system will be delivered with software offering a broad repertoire of helpful statistic analyses. This facilitates fast identification of repeated or systematically based errors.

If you require an individual solution, Intego offers free-of-charge feasibility studies based on sample parts. The prepared study will include a system design with draft specifications and a price estimate. Do not hesitate to contact us directly.

Your contact for the VELA string inspection

Andreas Eckl

+49 9131 61082-0

Contact