Thermography Basics

Raise the efficiency of your production

Inspection systems with cameras operating in the visible wavelength range usually cannot detect sub-surface defects and sometimes even those on the surface are hard to find. In these cases, thermography can be a solution. It is an imaging technique used to visualize the IR radiation intensity of objects by employing IR cameras.

Intego's know-how covers the complete process of thermographic measurement, from the type of thermographic excitation, the thermographic camera to the evaluation method used. Only the exact coordination of the used methods to each other delivers a convincing result.

Excitation methods

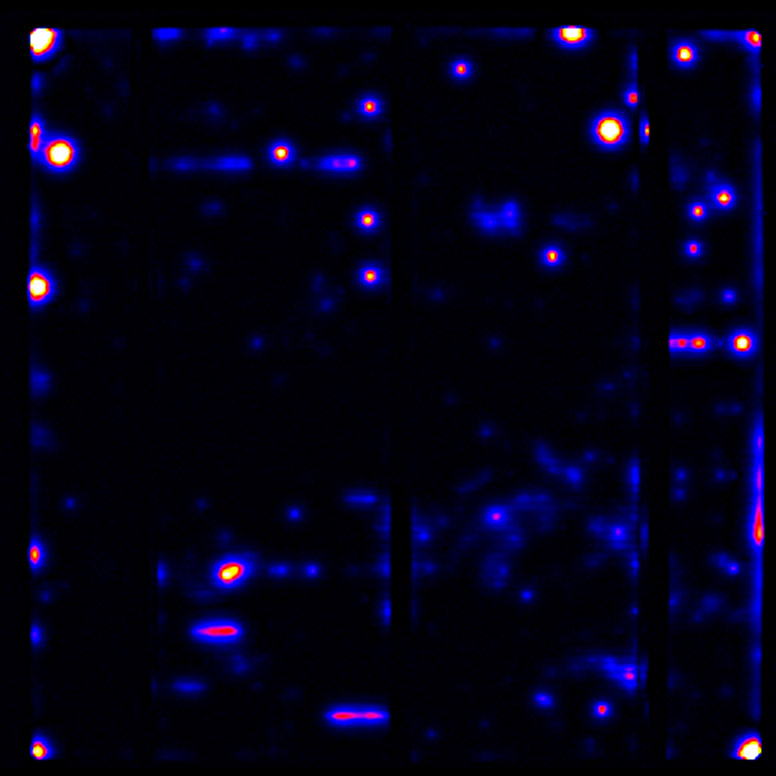

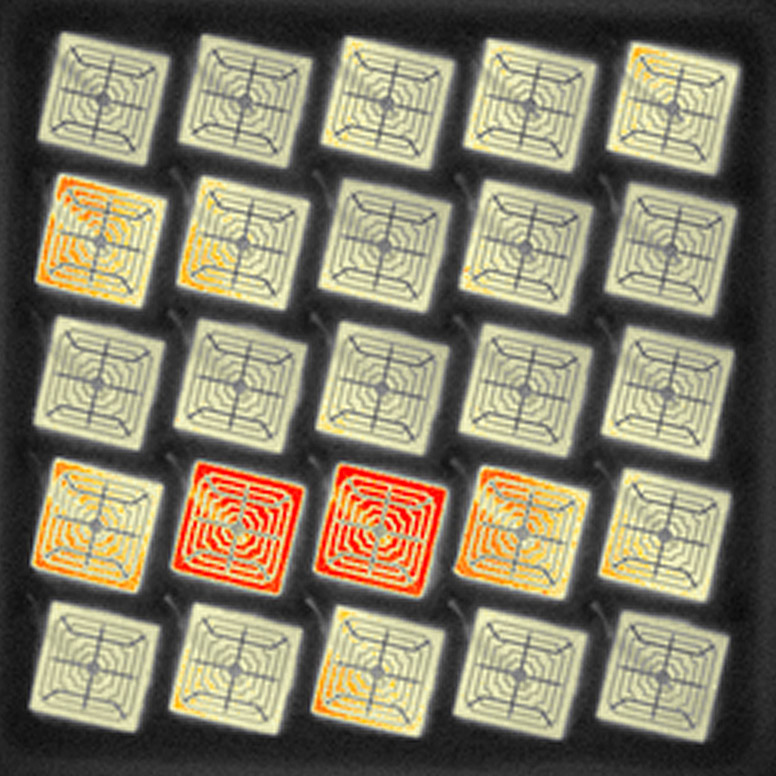

In passive thermography, the internal heat generation during operation of electrical components is used for measurement. If there is a fault and this is locally expressed by a temperature contrast of about 20 to 50 mK, it can often already be detected by means of a single thermographic image. In active thermography, the objects are excited electrically (direct connection, induction), mechanically (ultrasound, hot air) or by illumination (special lasers, LEDs, flash lamps).

Thermography camera

Intego develops and builds proprietary IR cameras. The models Spica 640 HS and Spica 1280 HS have an excellent price-performance ratio. The high resolution and frame rate as well as the sensitivity allow sensitive measurements in the range of < 25 mK and better. Details can be found on our topic page thermographic camera SPICA.

Evaluation methods

In passive thermography, simple and fast image evaluation methods can be used if the temperature contrasts are sufficiently high.

The lock-in thermography uses a periodic excitation with the so-called lock-in frequency, which is adjusted according to the required spatial resolution, sensitivity and estimated distance of the defect to the surface. This results in a longer measuring time, but the measurement is highly sensitive to temperature changes.

Pulse-phase thermography, on the other hand, uses a short pulse to generate a heat flow. Defects below the surface then lead to a changed surface temperature. Here, both the short measuring and evaluation time are advantageous, as well as a better visibility of fine details.

Performance data

Using thermography, various inspection objectives are achieved in a variety of applications.

- Determination of the surface temperature of objects (e.g. electronics, semiconductor devices, solar panels, brakes of motor vehicles and trains)

- Monitoring of welding processes, e.g. in plastic welding

- Testing the quality of welding points and welding seams

- Detection of pores, cracks, cavities/voids, delaminations, impurities and other defects in metals, ceramics, plastics, wood and composites

- Detection of electrical defects, cracks and impurities in solar materials

- Detection of electrical and mechanical defects in semiconductor devices and electronics

- Determination of the electrical quality of solar materials, e.g. charge carrier lifetime

- Determination of layer thicknesses, e.g. coating thickness of quartz crucibles

- Testing the quality of adhesive bonds

- Detection of gas emissions by spectrally resolved thermography (for example, CO2 has an absorption band at 4.3 µm)

Further option

Perhaps thermography is also the solution for your quality control. Please contact us.

Your contact for thermography

Dr. Dieter Karg

+49 9131 61082-250

dieter.karg@intego.de