Ceramics and Glass Inspection

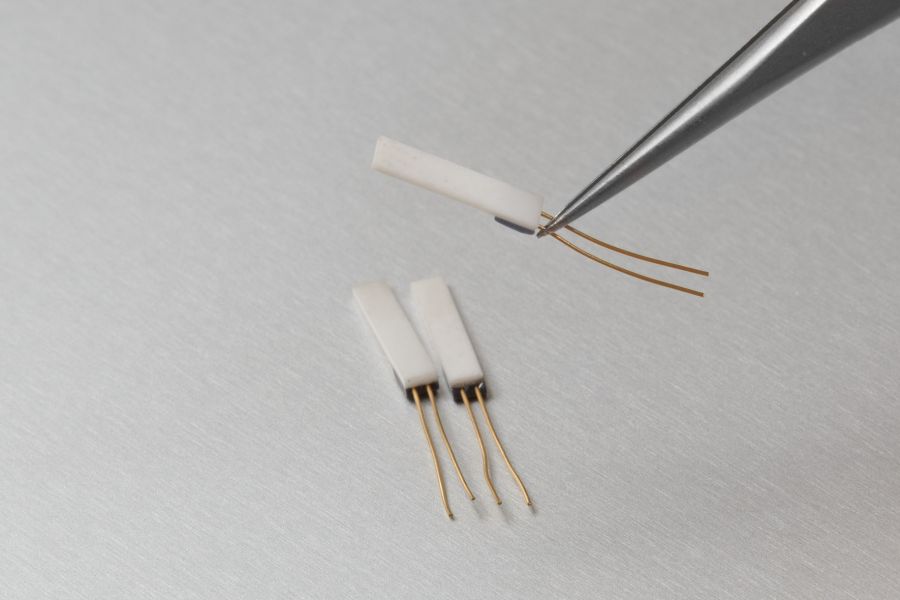

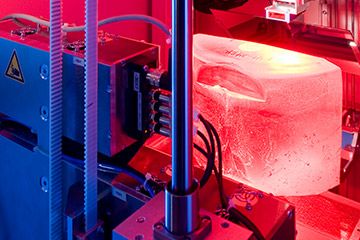

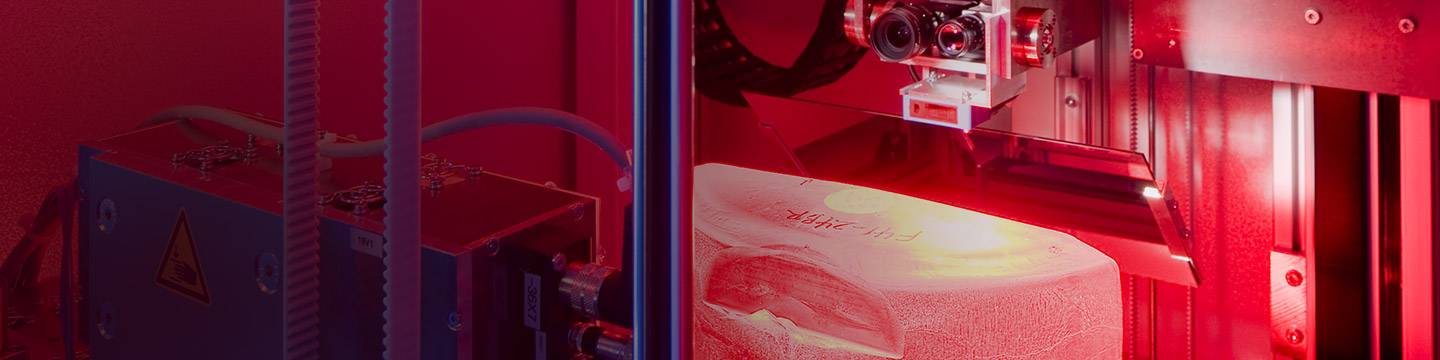

Due to their special material properties, ceramic and glass components are the basis of many high-tech products. The same properties make the production complex and costly. Substrate defects that lead to failure of finished components should be avoided at all costs. For this reason, early automated optical inspection is essential.

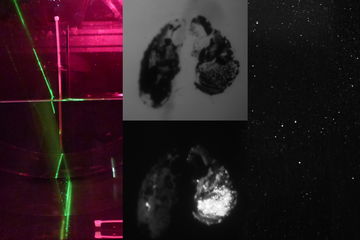

For the inspection of sapphire and quartz glass Intego has developed systems to detect both external and internal defects and can also provide cutting suggestions. Using index matching it is possible to test rough or uneven glass profiles.

For the inspection of ceramic components Intego offers solutions specifically tailored to the respective testing task. Our modular design uses standard components that have already been developed and tested and in most cases only requires minimal adaptation.