Weld Seam Inspection

Raise the efficiency of your production

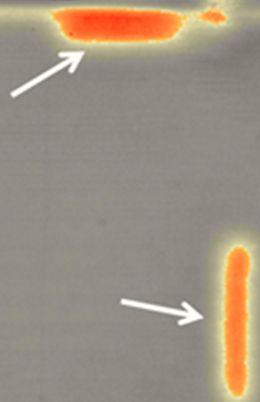

For the quality enhancement in the laser welding process Intego developed several inspection techniques to check the welding seam for deviations and defects. Especially in the automotive industry and for medical technologies, specifications are found which impose a testing of the joint for each part. For that reason Intego developed a series of inspection tools, which allows a precise assessment of the welding seam quality.

Performance data

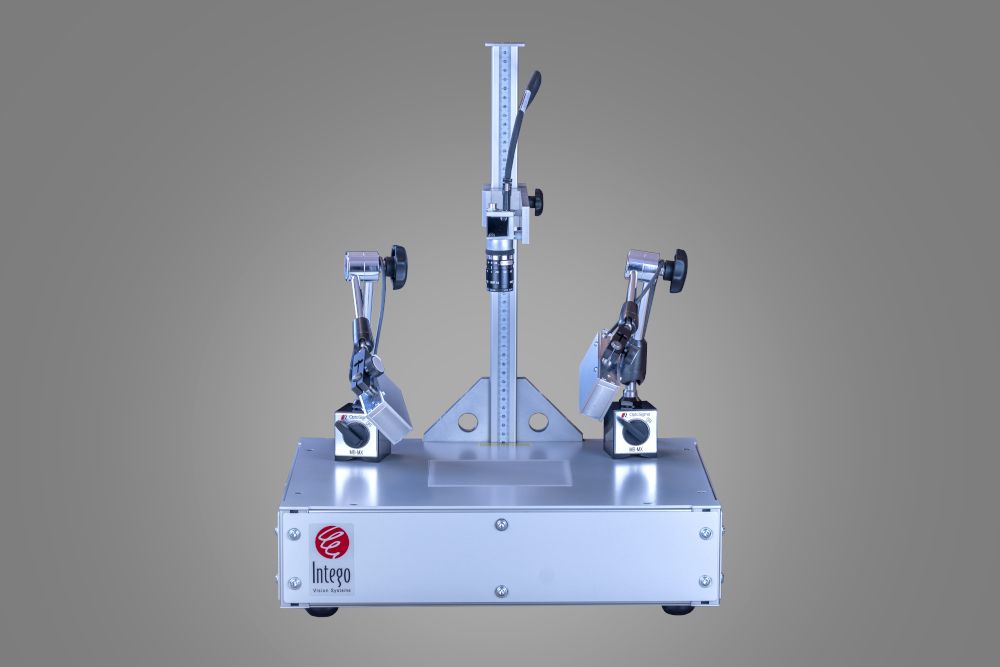

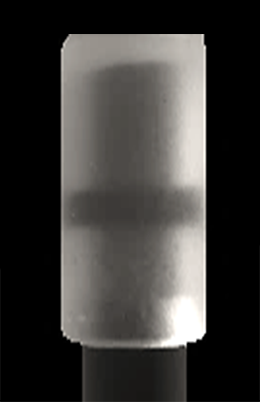

The infrared based inspection technology of Intego can be used to check the quality of flat and radial laser welding seams. Table-top tools as well as fully automated inline systems, suitable for integration in your production line, are available. The inspection wavelength, the resolution and the cycle time may be adjusted to fit your needs, as well as the interface to your automation in case of an inline inspection. To increase the efficiency of your production process, Integos EVOinspect transmission measurement systems provide you with helpful data and statistics.

Important system specifications

- Inspection of flat or round plastic parts

- Tool design either tabel-top or inline

- Illumniations available for NIR, SWIR or MWIR (standard 980 nm)

- Special NIR and SWIR/MWIR cameras (e.g. Intego's Spica 1280 SM HS)

- Inspection of weld seams (e.g. position, gaps, width), insertion depths (e.g. connectors), surface quality (e.g. dirt, inclusions)

- Intego's Inspector software, customer specific GUI

- Inline solutions for Evosys' laser systems

Further options

The interplay between the determination of the transmission characteristics of the transparent parts (Planar/Radial), the state-of-the-art laser through welding process of Evosys Laser GmbH and the pioneering weld seam inspection of Intego (Vision), can be seen as a new standard for assuring the quality of laser welding.

If you require an individual solution, Intego offers free-of-charge feasibility studies based on sample parts. The prepared study will include a system design with draft specifications and a price estimate. Do not hesitate to contact us directly.

Your contact for weld seam inspection

Dr. Steffen Oppel

+49 9131 61082-230

steffen.oppel@intego.de